Industrial Humanoid Robots: The New Focus in Smart Manufacturing

With continuous technological advancements and the rapid expansion of artificial intelligence, the momentum behind humanoid robots is growing stronger. They have become a new focal point in the industrial sector, gradually entering production lines and bringing new vitality to smart manufacturing. Industrial humanoid robots are crucial for improving production efficiency, ensuring work safety, addressing labor shortages, driving technological innovation, and enhancing quality of life. As technology progresses and application fields expand, industrial humanoid robots will play an even more significant role in the future.

For industrial humanoid robots, the controller is their core brain, the foundation of industry development, and it plays a crucial role in the robot’s performance. Based on continuous research and application experience, we believe industrial humanoid robots need to meet the following functional and performance adjustments:

1.As the core brain of humanoid robots, the edge computing central processor needs to support multiple sensors such as multi-cameras, radars, and other devices.

2.They must have the capability to process and make real-time decisions with large amounts of data. Industrial AI edge computers can process sensor and image data in real-time, making decisions to guide precise operations and navigation.

3.They need AI learning and high real-time inference capabilities, which are vital for autonomous operation in dynamic environments.

After years of industry accumulation, we have developed the highest standard robot central processor system. It boasts powerful hardware performance, rich interfaces, and robust software functions, providing multi-dimensional stability.

E-Smart IPC

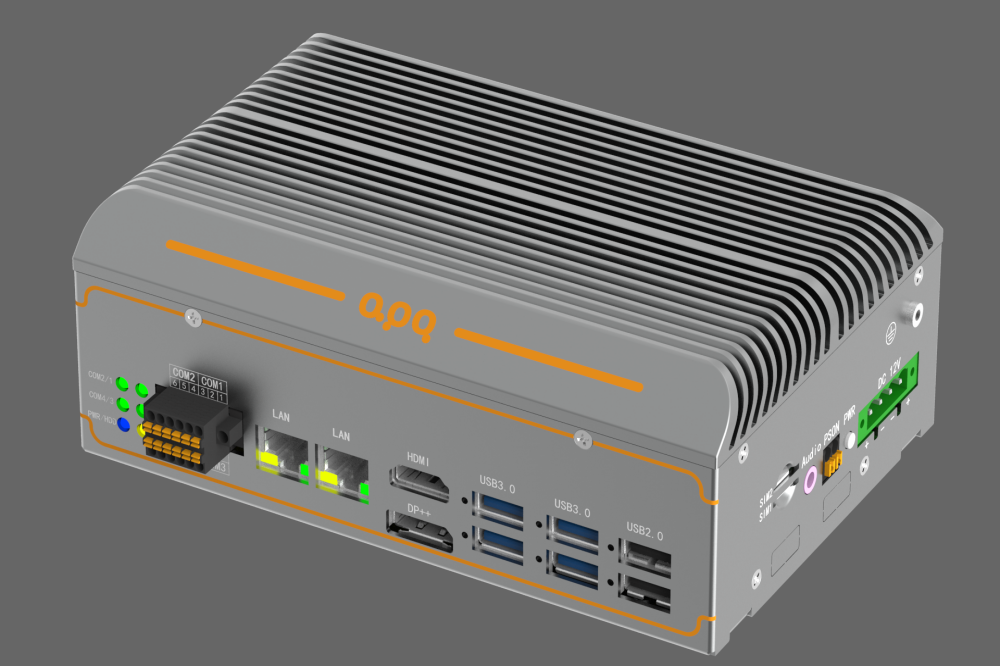

As a service provider focused on industrial AI edge computing, we have developed complementary IPC Assistant and IPC Manager software products based on traditional IPC hardware, forming the industry’s first E-Smart IPC. These are widely used in vision, robotics, motion control, and digital fields. The AK series and TAC series are key intelligent industry controllers equipped with IPC Assistant and IPC Manager, serving as the stable, reliable “core brain” for industrial humanoid robots.

As the flagship E-Smart IPC product launched in 2024, the AK series adopts a 1+1+1 model—main host with primary, secondary, and software modules. It meets the needs of various applications like vision, motion control, robotics, and digitalization. It supports Intel CPUs from 6th to 13th gen, with default dual Intel Gigabit networks expandable to ten. It also supports 4G/WiFi, M.2 (PCIe x4/SATA) storage, and features a high-strength aluminum body adaptable to various industrial scenarios. It supports desktop, wall, and rail installations, as well as modular isolated GPIO, isolated serial ports, and light control expansion.

The TAC series is a compact computer with a high-performance GPU, designed to be integrated into various devices, providing intelligent capabilities. It offers powerful computing and inference capabilities for real-time AI applications in industrial humanoid robots. The TAC series supports platforms like NVIDIA, Rockchip, and Intel, with maximum computing power up to 100 TOPs (INT8). It features Intel Gigabit network support, M.2 (PCIe x4/SATA) storage, and MXM/aDoor module expansion, housed in a high-strength aluminum body. Its quasi-rail and anti-loosening, anti-vibration design ensure controller stability and reliability during robot operation. The TAC series provides a stable, reliable “core brain” for many well-known industry enterprises.

IPC Assistant + IPC Manager

To address the operational challenges industrial humanoid robots face, we developed IPC Assistant and IPC Manager for autonomous operation and centralized maintenance, ensuring stable operation and efficient management. IPC Assistant remotely manages individual devices for safety, monitoring, warning, and automated operations, visualizing operational and health statuses, providing timely warnings for anomalies, and ensuring stable operation to enhance factory efficiency and reduce maintenance costs. IPC Manager manages multiple connected devices on the production line, supporting adaptation, transmission, coordination, and automated operation using standard IoT frameworks. It offers massive device management, secure data transmission, and efficient data processing.

As Industry 4.0 progresses, high-tech devices like robots are poised for significant growth. Industrial humanoid robots enhance flexible manufacturing processes and are highly regarded in the smart manufacturing industry. Our mature application cases and comprehensive solutions, including the innovative E-Smart IPC, will continue to provide stable, reliable, intelligent, and secure “core brains” for industrial humanoid robots, empowering the digital transformation of industrial applications.